Custom Metallic Hologram Paper Bags for Gift High End Glitter Laser Paper Bags for Shopping

What is Hologram Paper Bag?

A hologram paper bag is a type of paper bag that incorporates holographic elements into its design. Holographic materials create a three-dimensional effect, producing a dynamic and eye-catching display of colors and patterns when viewed from different angles.

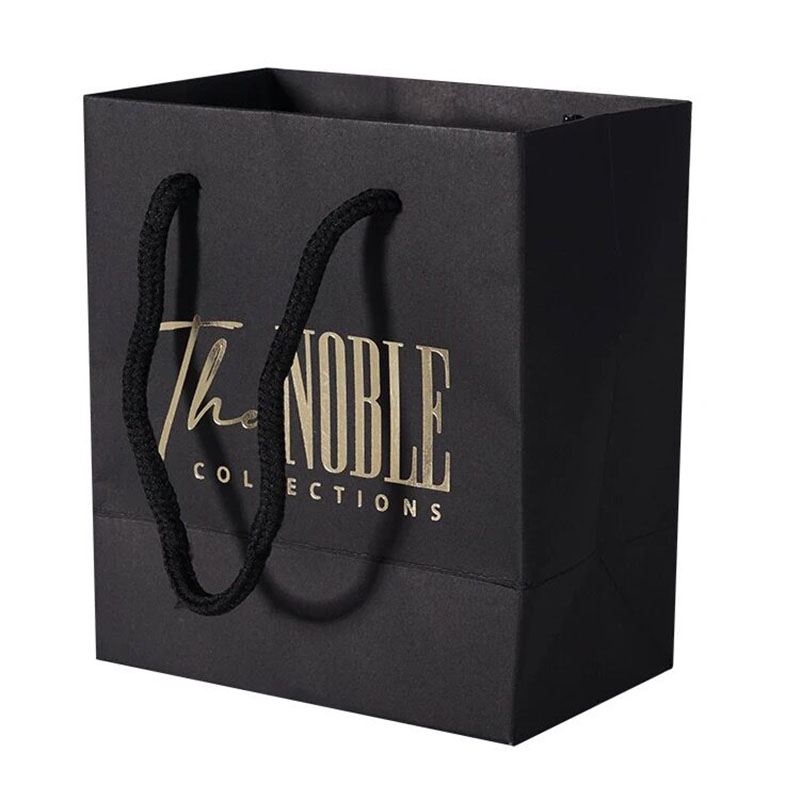

Hologram paper bags are often used for promotional and packaging purposes, as they attract attention and create a visually appealing presentation. They can be customized with brand logos, designs, or messages to enhance brand visibility and create a memorable impression.

The holographic effect on these bags is achieved through a process called holographic foil stamping or holographic printing. This involves applying a layer of holographic film or foil onto the paper bag surface, which reflects light in a way that creates the illusion of depth and movement.

Hologram paper bags are popular in industries such as fashion, cosmetics, electronics, and luxury goods, where a visually striking packaging solution is desired. They offer a unique and futuristic appearance, making them stand out from traditional paper bags and adding a touch of sophistication to the overall presentation.

The Material & Thickness of Hologram Paper Bags

Hologram paper bags for gift can be made from a variety of materials, depending on the clients and specific requirements. The most common material used is paper, which can be either virgin paper or recycled paper. Virgin paper is made from fresh wood pulp, while recycled paper is made from post-consumer waste paper.

In terms of thickness, hologram paper bags for gift can vary depending on their intended use and the preferences of the manufacturer or customer. The thickness of the paper used for these bags is typically measured in grams per square meter (gsm) or pounds per ream (lb). Common thicknesses for hologram paper bags range from 120 gsm to 200 gsm (or 80 lb to 130 lb).

The thickness of the paper used for hologram paper bags for gift is chosen based on factors such as the strength and durability required, the weight of the items to be carried, and the desired aesthetic appearance. Thicker paper tends to be more durable and can handle heavier loads, while thinner paper may be more lightweight and flexible.

It's important to note that the holographic effect on these bags is typically achieved through a special holographic film or foil that is applied to the paper surface. This holographic material does not significantly affect the thickness or strength the paper itself.

The Handle Styles of Hologram Paper Bags

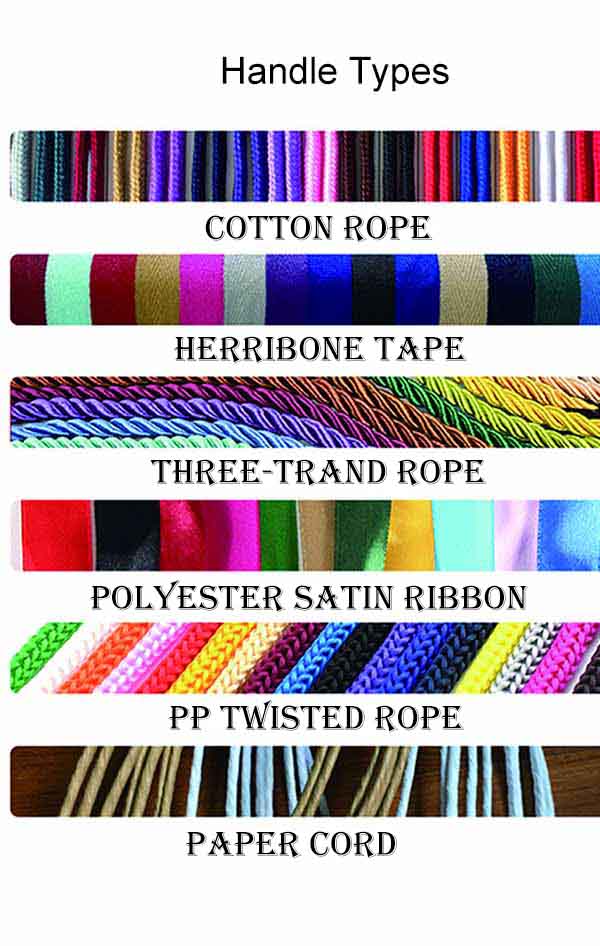

Hologram paper bags can have various handle styles, depending on the design and purpose of the bag. Here are some common handle styles found in hologram paper bags:

1. Twisted paper handles: Twisted paper handles are made by twisting and folding strips of paper to create a sturdy handle. This style is commonly used in paper bags and provides a comfortable grip for carrying.

2. Ribbon handles: Ribbon handles are made from decorative ribbons that are attached to the bag. They add a touch of elegance and can be customized with different colors and designs to match the holographic pattern of the bag.

3. Die-cut handles: Die-cut handles are created by cutting out a handle shape directly from the bag material. This style offers a clean and seamless look and is often used in bags with unique or intricate holographic designs.

4. Rope handles: Rope handles are made from durable and thick ropes, usually made of cotton or nylon. They are attached to the bag through reinforced holes or metal eyelets. Rope handles provide a more substantial and comfortable grip, making them suitable for heavier items.

5. Plastic or metal handles: Some hologram paper bags may feature plastic or metal handles for added durability and a more luxurious look. These handles are typically attached to the bag through grommets or other hardware.

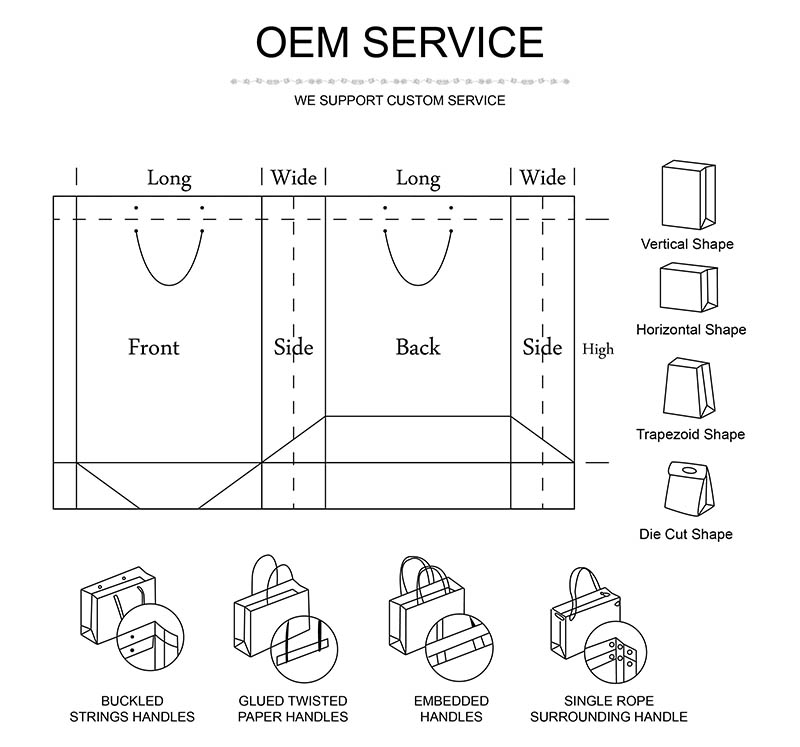

We Support OEM Service

1. Design and customization: The client provides us with their desired design, dimensions, and specifications for the paper bags. This includes details such as size, shape, color, printing artwork, handle style, and any specific features or requirements.

2. Material selection: The client and we discuss and select the type of paper material to be used for the bags. This can include options like kraft paper, coated paper, art paper, or specialty paper, depending on the client's preferences and needs.

3. Printing and customization: We uses the provided design and specifications to create a prototype or sample of the paper bag. Once the client approves the sample, We proceeds with mass production. This involves printing the desired artwork, applying any special finishes or effects, and incorporating any customizations requested by the client.

4. Quality control: Throughout the production process, we conducts quality control checks to ensure that the paper bags meet the client's specifications and standards. This includes checking for print quality, proper dimensions, strength and durability, and overall construction.

5. Packaging and delivery: Once production is complete, the paper bags are packaged according to the client's requirements, such as the desired quantity per carton or pallet. We then arranges for the delivery or shipment of the finished bags to the client's designated location.

In an OEM service arrangement, we produce the paper bags according to the client's specifications and branding requirements. The client typically has ownership and branding rights over the produced paper bags. Our role is to provide expertise in manufacturing and ensure the quality and timely delivery of the customized paper bags.

Printing Methods on Laser Paper Bags for Shopping

When it comes to printing modes for laser paper bags, there are a few common options available. These printing modes determine how the design and artwork are applied to the paper bags. Here are three popular printing modes for laser paper bags:

1. Offset printing: Offset printing is a traditional and widely used printing method that involves transferring ink from a metal plate to a rubber blanket, and then onto the paper. It offers high-quality and precise printing results, making it suitable for complex designs, fine details, and vibrant colors. Offset printing is ideal for large-scale production runs.

2. Digital printing: Digital printing is a modern printing method that involves directly transferring the design from a digital file onto the paper. It offers quick turnaround times, cost-effective production for smaller quantities, and the ability to easily customize each bag with unique designs. Digital printing is suitable for simpler designs and shorter print runs.

3. Flexographic printing: Flexographic printing, also known as flexo printing, is a versatile and efficient printing method commonly used for packaging materials. It involves a flexible relief plate that transfers ink onto the paper. Flexographic printing is well-suited for simple designs, solid colors, and large print areas. It is often used for high-volume production runs.

Each printing mode has its own advantages and considerations, such as cost, print quality, production speed, and customization options. The choice of printing mode for laser paper bags depends on factors such as the complexity of the design, the desired print quality, the quantity needed, and the budget constraints. It is recommended to consult with us to determine the most suitable printing mode for your specific requirements.

Surface Finishing On Laser Paper Bags for Shopping

Surface finishing refers to the additional treatments or enhancements applied to the surface of laser paper bags after printing. These finishes can enhance the appearance, durability, and overall quality of the bags. Here are some common surface finishing options for laser paper bags:

1. Lamination: Lamination involves applying a thin layer of plastic film to the surface of the paper bag. It provides a glossy or matte finish and adds durability and water resistance. Lamination can also enhance the vibrancy of colors and protect the printed design from fading or scratching.

2. Varnishing: Varnishing is the process of applying a clear coating to the surface of the paper bag. It adds a glossy or matte finish and provides protection against moisture, dirt, and abrasion. Varnishing can also enhance the colors and details of the printed design.

3. Spot UV: Spot UV involves applying a glossy or matte coating to specific areas of the bag, creating a contrast between the coated and uncoated areas. It adds a tactile and visual effect, highlighting specific elements of the design. Spot UV can be used to create a glossy logo or text on a matte background, for example.

4. Embossing or Debossing: Embossing and debossing are techniques that create raised or recessed patterns or designs on the surface of the paper bag. Embossing raises the design, while debossing creates a depressed or sunken effect. These finishes add texture and a tactile element to the bag, enhancing its visual appeal.

5. Foil Stamping: Foil stamping involves applying a metallic or colored foil onto the bag's surface using heat and pressure. It creates a shiny and reflective effect, adding a luxurious and premium look to the bag. Foil stamping can be used for logos, text, or other design elements.

6. Holographic Effects: Holographic effects involve applying a special film or coating to the bag's surface, creating a holographic or iridescent appearance. This finish adds a unique and eye-catching effect, making the bag stand out.

These surface finishing options can be combined or customized to create unique and visually appealing laser paper bags. The choice of finish depends on the desired aesthetics, branding requirements, and budget considerations.