Recycled Mini Brown Paper Bags Biodegradable Paper Shopping Bags Wholesale Fast Food Bag

Material and Weight Option on Mini Brown Paper Bags

1. Brown Kraft Paper: Brown Kraft paper is the most common material used for Kraft paper bags. It is made from unbleached wood pulp, giving it a natural brown color. Brown Kraft paper bags are known for their strength and durability. The weight options for mini brown paper bags typically range from 70 GSM (grams per square meter) to 120 GSM.

2. White Kraft Paper: White Kraft paper is a bleached version of Kraft paper, resulting in a white or off-white color. It offers a clean and professional look and is often used for high-end or customized Kraft paper bags. The weight options for Biodegradable Paper Shopping Bags are similar to those of brown Kraft paper, ranging from 70 GSM to 120 GSM.

3. Recycled Kraft Paper: Recycled Kraft paper is made from post-consumer waste paper, making it an eco-friendly option. It has a slightly rougher texture and a speckled appearance due to the recycled fibers. The weight options for recycled fast food bags are similar to those of brown and white Kraft paper, ranging from 70 GSM to 120 GSM.

4. Heavy-Duty Kraft Paper: Heavy-duty Kraft paper is a thicker and more robust option, designed to carry heavier items or withstand rough handling. The weight options for heavy-duty Kraft paper bags typically start from 150 GSM and can go up to 200 GSM or more.

The weight of the Kraft paper refers to the thickness and density of the paper. A higher GSM indicates a thicker and heavier paper, which generally offers more strength and durability. The choice of material and weight depends on factors such as the intended use, the weight of the items to be carried, and the desired level of sturdiness.

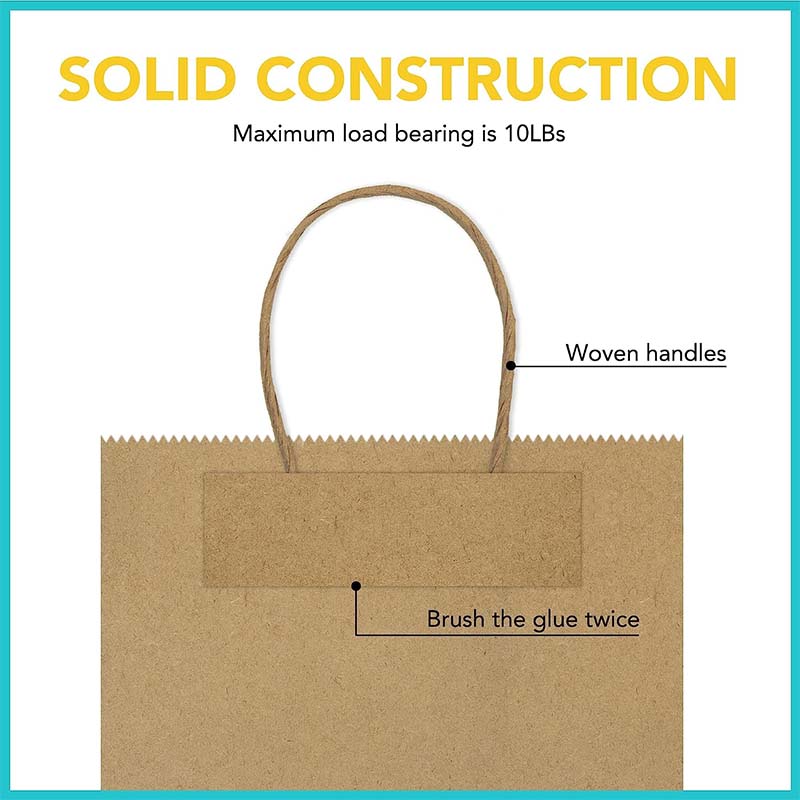

The Handle Options of Biodegradable Paper Shopping Bags Wholesale

1. Twisted Paper Handles: Twisted paper handles are a popular choice for paper shopping bags. These handles are made from twisted paper cords that are securely attached to the bag. Twisted paper handles are sturdy and comfortable to hold, making them suitable for carrying heavier items.

2. Flat Paper Handles: Flat paper handles are another option for paper shopping bags. These handles are made from flat strips of paper that are attached to the bag. Flat paper handles provide a sleek and minimalist look and are suitable for lighter items.

3. Rope Handles: Rope handles are often used for more upscale or luxury paper shopping bags. These handles are made from sturdy ropes, typically made of cotton or synthetic materials. Rope handles offer a more sophisticated and elegant look and are comfortable to hold.

4. Die-Cut Handles: Die-cut handles are cut-out handles that are integrated into the body of the paper shopping bag. These handles are typically reinforced with additional layers of paper or plastic for added strength. Die-cut handles provide a clean and seamless look and are commonly used for retail or promotional bags.

5. No Handles: Some paper shopping bags may not have any handles at all. These bags are designed to be carried by hand or placed inside larger bags or containers. Bags without handles are often used for packaging or gift purposes.

The choice of handle option depends on factors such as the weight and size of the items to be carried, the desired aesthetic, and the budget. It's important to consider the functionality and durability of the handles to ensure they can withstand the intended usage of the paper shopping bag.

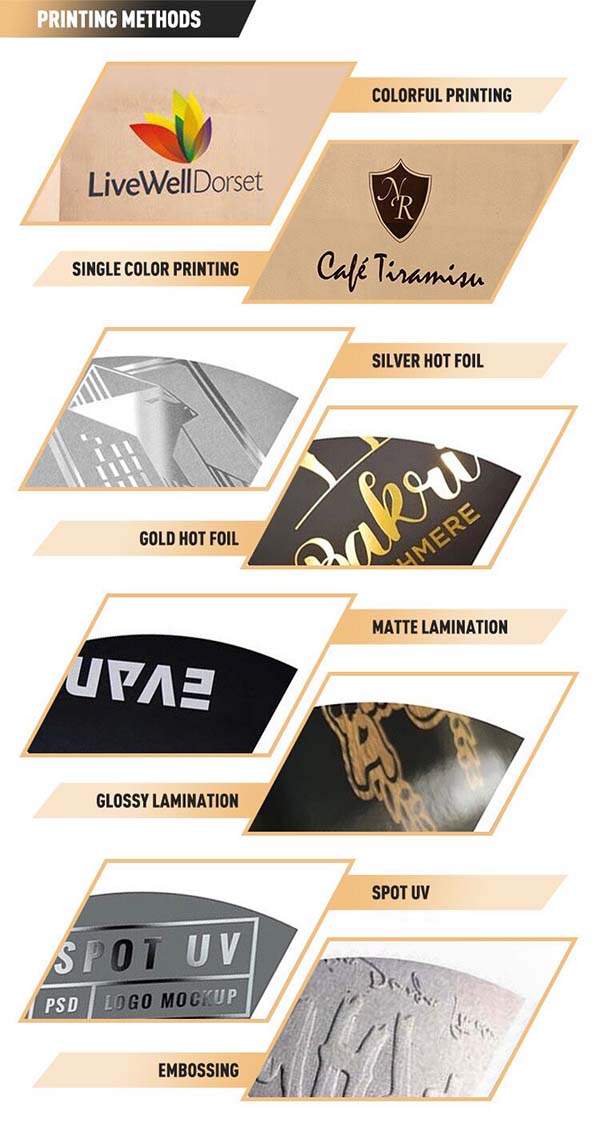

The Printing Modes of Fast Food Bags

1. Flexographic Printing: Flexographic printing is a popular printing method for fast food bags. It involves transferring ink onto the bag's surface using flexible rubber or polymer plates. Flexographic printing is cost-effective, fast, and suitable for large print runs. It can produce vibrant colors and sharp images.

2. Offset Printing: Offset printing is a high-quality printing method commonly used for fast food bags. It involves transferring ink from a plate to a rubber blanket, which then applies the ink to the bag's surface. Offset printing offers precise and detailed prints, making it suitable for intricate designs, gradients, and fine text.

3. Digital Printing: Digital printing is a modern printing method that uses digital files to directly print onto the fast food bags. It offers flexibility, quick turnaround times, and the ability to print variable data or personalized designs. Digital printing is ideal for smaller print runs or when customization is required.

4. Screen Printing: Screen printing involves transferring ink through a mesh screen onto the bag's surface. It is commonly used for fast food bags that require bold and opaque prints. Screen printing is suitable for simple designs with few colors and can provide a textured or raised effect on the bag.

5. Hot Stamping: Hot stamping is a printing method that uses heat and pressure to transfer metallic foils or colored films onto the bag's surface. It is often used to add a shiny or metallic finish to logos, text, or designs. Hot stamping can create an eye-catching and premium look on fast food bags.

The choice of printing mode depends on factors such as the desired print quality, budget, quantity, and complexity of the design. Each printing mode has its own advantages and considerations, so it's important to choose the most suitable option based on the specific requirements of the fast food bag

The Printed Color Choice of Mini Brown Paper Bags

1. Black: Black is a classic and versatile color choice for mini brown paper bags. It can create a sleek and sophisticated look, making it suitable for various brands and designs.

2. White: White is another popular color choice for printed mini brown paper bags. It offers a clean and minimalist look, allowing the printed design or logo to stand out prominently.

3. Metallic Colors: Metallic colors like gold, silver, or bronze can add a touch of elegance and luxury to mini brown paper bags. They can be used for highlighting specific elements or creating a premium look.

4. Pantone Colors: Pantone colors are a standardized color matching system used in the printing industry. They offer a wide range of vibrant and precise colors that can be used to match specific brand colors or create eye-catching designs.

5. Custom Colors: Some brands may opt for custom colors that align with their specific branding guidelines or design preferences. These colors can be created by mixing different ink pigments to achieve a unique and personalized look.

It's important to consider the contrast and legibility of the printed colors against the brown background of the paper bag. High contrast colors or complementary color combinations can ensure that the printed design is easily visible and readable.

Ultimately, the choice of printed colors for mini brown paper bags should align with the brand identity, target audience, and overall design concept. It's recommended to work with a professional printer or graphic designer to ensure the best results

The Manufacturing Process of Fast Food Bags

typically involves several steps. Here is a general overview of the process:on the specific requirements of the brown fast food bags..

1. Material Selection: The first step is to select the appropriate material for the fast food bags. The most common material used is kraft paper, which is a strong and durable type of paper made from wood pulp.

2. Paper Preparation: The selected kraft paper is then processed and prepared for bag production. This involves cutting the paper into the desired size and shape for the bags.

3. Printing: If the brown fast food bags require printing, this step involves applying the desired designs, logos, or branding onto the prepared paper. Printing can be done using various methods such as flexographic printing, offset printing, digital printing, or screen printing, as mentioned earlier.

4. Bag Formation: Once the paper is printed (if necessary), it is then folded and glued to form the shape of the bag. This is typically done using automated machinery that can fold and glue the paper accurately and efficiently.

5. Handle Attachment: If the brown fast food bags require handles, this step involves attaching the handles to the bags. Handles can be made of various materials such as paper, plastic, or rope, as discussed earlier. The handles are typically secured to the bags using adhesive or stitching.

6. Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure that the brown fast food bags meet the required standards. This includes checking for proper printing, accurate folding and gluing, secure handle attachment, and overall bag integrity.

7. Packaging and Distribution: Once the brown fast food bags pass the quality control checks, they are then packaged and prepared for distribution. They may be bundled, boxed, or shrink-wrapped, depending on the specific packaging requirements.

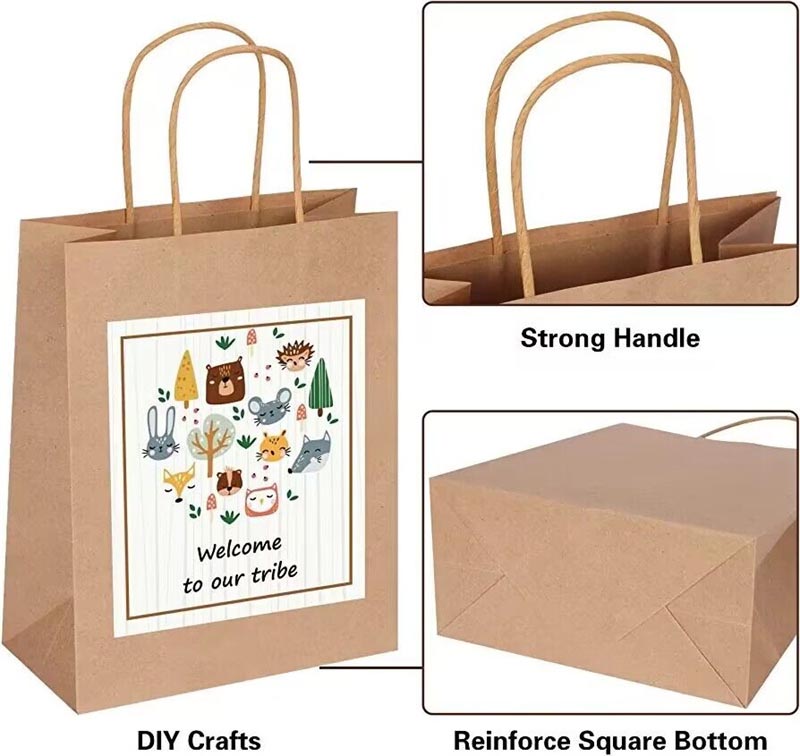

Details on Recycled Biodegradable Paper Shopping Bags Wholesale Fast Food Bag Mini Brown Paper Bag

Kraft Paper Material

The raw material selected from high level kraft paper, Excellent thickness & toughness Recyclable & biodegradable features.Greenenvironmental properties.

Strong Handles

Durable handle & Strong bearing capacity · German Henkel bondingtechnology.

Tidy Sawtooth

Advanced Automatic Machine Production, Keep Overall Cost Down and Fast Delivery.

Inside Finishing

Support BOPP sealable (Anti-oil,waterliquid) Full or Partial PP for choice.

Non-toxic Water Based Inkand Manroland Printing Machine, Ensure Best Printing Effect.

Packing & Shipping on Eco-friendly White Kraft Paper Bags