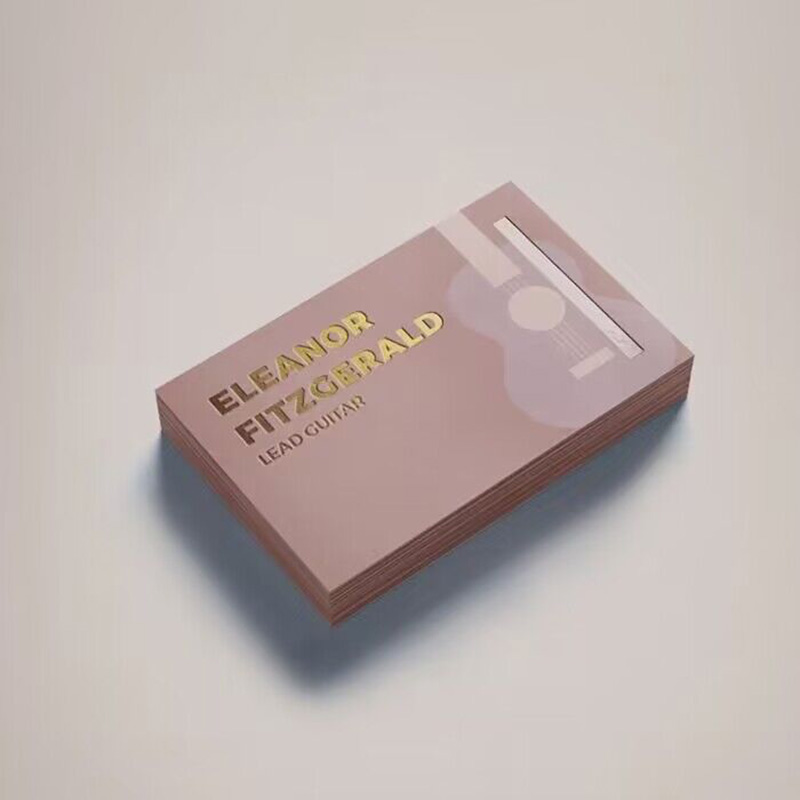

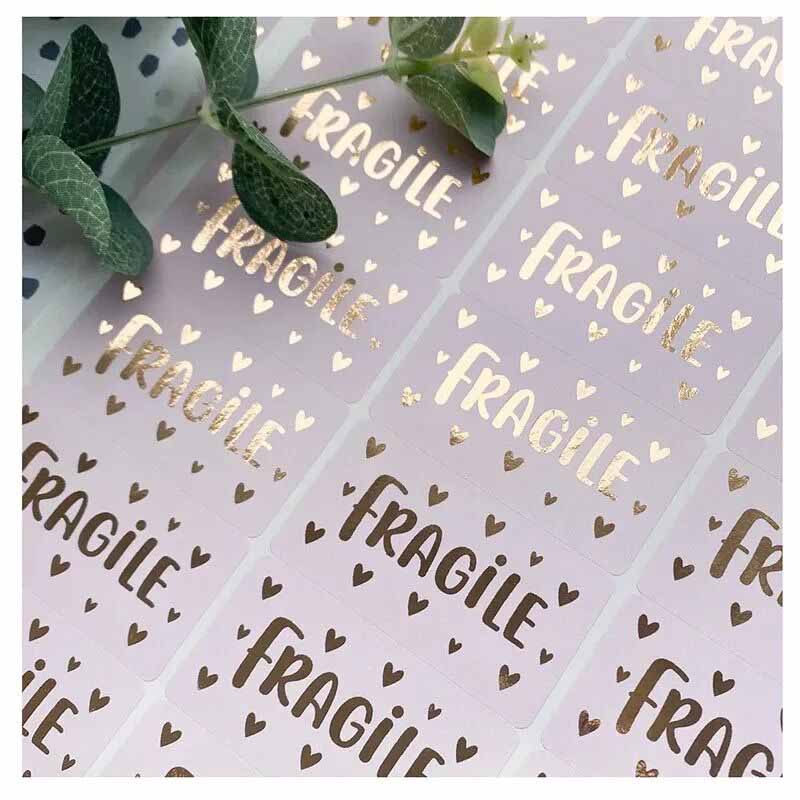

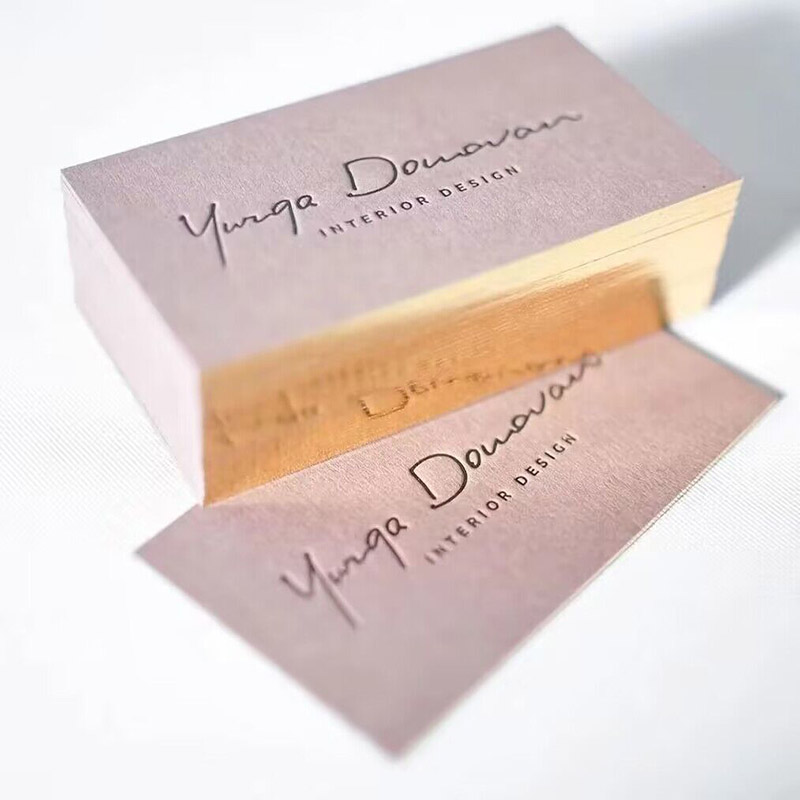

Custom Luxury Letterpress Embossing Business Holiday Cards Gold Foil Stamping Visiting Card

Embossing is a popular technique used to add texture and dimension to paper business cards. It involves creating raised or recessed designs on the surface of the card by applying pressure with a die.

To emboss paper business cards, a metal die with the desired design or logo is created. The die is then pressed onto the paper using a combination of heat and pressure, resulting in a raised impression on one side of the card and a corresponding debossed impression on the other side.

Embossing can be done on various paper materials, such as cardstock or specialty textured papers, to add a tactile element and enhance the visual appeal of the business card. It can be used to highlight important details, logos, or patterns, making the card stand out and leave a lasting impression.

Embossed paper business cards are often associated with elegance and professionalism. The raised texture adds a sense of luxury and sophistication, making them a popular choice for individuals or companies looking to make a memorable impact.

There are various paper materials that can be used for embossed business cards. Here are some popular options:

1. Matte Cardstock: This is a smooth and non-glossy paper that creates a sophisticated and professional look. It is often chosen for its elegant appearance and ability to showcase embossed details.

2. Glossy Cardstock: This paper has a shiny finish that enhances the visual impact of embossing. It gives a polished and vibrant look to the business cards.

3. Linen Paper: Linen paper has a textured surface that adds a touch of luxury and elegance to embossed designs. It provides a unique tactile experience and gives the cards a high-quality feel.

4. Recycled Paper: If you prefer an eco-friendly option, you can choose recycled paper for your embossed business cards. It is made from post-consumer waste and offers a rustic, natural look.

5. Metallic Paper: Metallic paper has a metallic sheen that adds a glamorous and eye-catching effect to embossed designs. It is available in various colors, such as gold, silver, and bronze, allowing for stunning visual effects.

These are just a few options, and there are many others to explore based on your specific preferences and requirements. It's important to consider factors like durability, cost, and the overall impression you want to create when selecting the paper material for embossed business cards.

Introduction on Letterpress Printing Method

Letterpress printing is a traditional printing technique that involves pressing inked metal or wooden type onto paper to create a raised impression. It is a popular choice for paper business holiday cards due to its elegant and tactile results.

To create letterpress printed business holiday cards, a custom metal or wooden plate is made with the desired design or message. Ink is applied to the plate, and then the plate is pressed onto the paper using a letterpress machine. The pressure from the machine transfers the ink onto the paper, creating a debossed impression.

Letterpress printing offers a unique and artisanal look to business holiday cards. The tactile quality of the raised impression adds a sense of luxury and craftsmanship. It also allows for a wide range of paper options, such as textured or specialty papers, to enhance the overall aesthetic.

The process of letterpress printing can be time-consuming and requires expertise, making it a premium printing option. However, the result is a beautifully crafted and memorable business holiday card that stands out and leaves a lasting impression on recipients.

The manufacturing process of visiting cards with letterpress printing typically involves the following steps:

1. Design: The first step is to create or finalize the design for the visiting card. This can be done using graphic design software or by working with a professional designer.

2. Plate Creation: Once the design is finalized, a custom metal or wooden plate is created. This plate will have the desired design or text raised on its surface. The plate is typically made by etching or engraving the design onto the metal or wood.

3. Ink Preparation: The next step is to prepare the ink for printing. Letterpress inks are usually oil-based and come in a variety of colors. The ink is mixed and adjusted to achieve the desired color and consistency.

4. Press Setup: The letterpress machine is set up for printing. This involves adjusting the pressure, aligning the plate, and preparing the paper feed.

5. Printing: The ink is applied to the plate, and the plate is then pressed onto the paper. The pressure from the machine transfers the ink onto the paper, creating a raised impression. Each card is printed individually, and the process is repeated for each card.

6. Drying and Finishing: After printing, the cards need to dry before any further finishing processes can be applied. This can be done by allowing them to air dry or using drying racks. Once dry, additional finishing touches such as trimming, edge painting, or adding special coatings can be done to enhance the appearance of the cards.

7. Quality Control and Packaging: The final step is to inspect the printed cards for any imperfections or errors. Once they pass the quality control check, the cards are packaged and prepared for delivery or distribution.

The Benefits and Advantages of Embossed Visiting Cards

1. Enhanced Visual Appeal: Embossing adds a three-dimensional effect to the design of the visiting card, making it visually striking and attention-grabbing. The raised areas create a tactile experience that stands out from flat printed cards.

2. Professional and High-End Look: Embossed paper visiting cards exude a sense of professionalism and sophistication. The raised design adds a touch of elegance and luxury, making a strong impression on recipients.

3. Increased Durability: The embossing process strengthens the paper, making it more resistant to wear and tear. This ensures that the visiting cards maintain their quality and appearance for a longer time, even with frequent handling.

4. Unique and Memorable: Embossed designs create a unique and distinctive look for visiting cards. The tactile experience of running fingers over the raised areas leaves a lasting impression on recipients, making the card more memorable.

5. Versatility in Design: Embossing can be applied to various elements of the visiting card, such as logos, text, or patterns. This allows for creative and customized designs that align with the branding and personality of the individual or business.

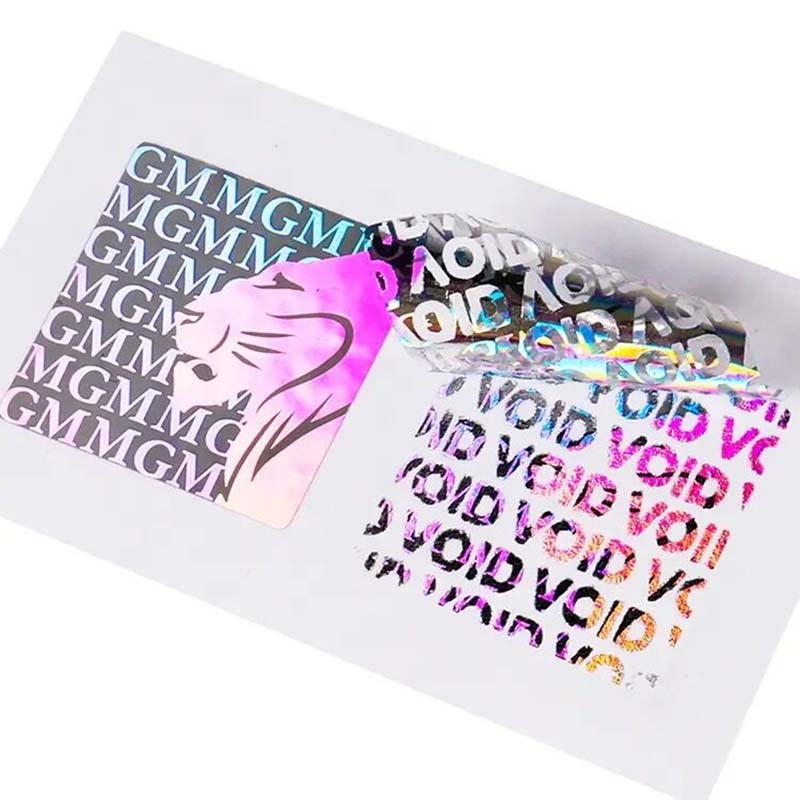

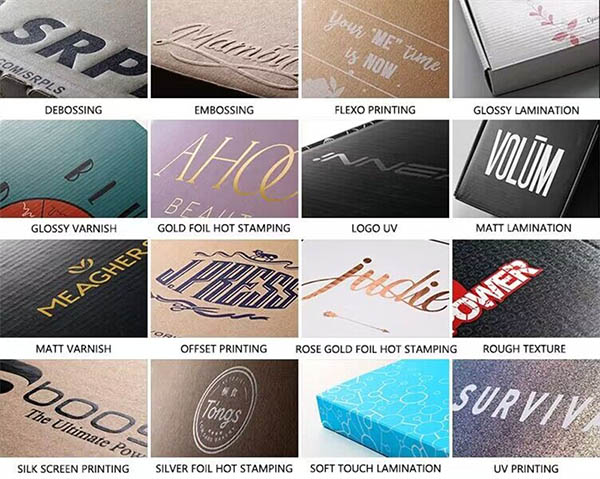

6. Complement to Other Printing Techniques: Embossing can be combined with other printing techniques, such as foil stamping or spot UV coating, to further enhance the visual impact of the visiting card. This combination adds depth and texture to the design, creating a multi-dimensional effect.

7. Reflects Attention to Detail: Embossed paper visiting cards demonstrate a commitment to quality and attention to detail. They convey a sense of professionalism and care, which can positively influence the perception of the individual or business.

Overall, embossed paper visiting cards offer a unique and visually appealing option for professionals and businesses looking to make a memorable impression. The tactile experience, durability, and customization possibilities make them stand out from traditional flat printed cards.

FAQ

Q1: What kind of information in need to provide for quotation?

- Please provide your products' quantity, size, pages of cover and text, colors on both sides of sheets(eg,full color both sides), paper type and paper weight ( eg. 128gsm glossy art paper), surface finish ( eg. glossy / matt lamination, UV), binding way ( eg. perfect binding, hardcover).

Q2: When we create the artwork, what kind of format is available for printing?

- The popular ones: PDF, AI,CorelDRAW,PSD.

- Bleed size: 3-5mm.

Q3: Can I get a sample before placing an order? How About The Mass Production?

- The sample fee is free if it is our design, but you need to pay the freight. Also we can make sample according to your design and your requirements. But sample cost is needed. Usually sample cost can be refundable after placing the order.

- The samples time is about 1-3 days. The lead time for mass production based on order quantity, finishing, etc., usually 7-10 working days is enough.

Q4: Can We Have Our Logo or Company Information on Your Products or Package?

- Sure. Your Logo can show on the products by Printing, UV Varnishing, Hot Stamping, Embossing, Debossing, Silk-screen Printing or Sticker a label on it.